How Mulberry Silk is Made: From Silkworm to Luxurious Fabric

Soft, smooth, and naturally elegant, mulberry silk is one of the most luxurious and sought-after fabrics in the world. Known for its exceptional softness, natural luster, and skin-friendly qualities, this silk has been prized for centuries. We thank Lady Leizu, the legendary Empress credited with the discovery of silk over 5,000 years ago. Her wisdom and curiosity sparked a tradition that still inspires awe today.

But have you ever wondered how this delicate material comes to life?

In this article, we’ll take you behind the scenes to explore How Mulberry Silk is Made: From Silkworm to Luxurious Fabric. Whether you’re a silk enthusiast or just curious, you’re about to discover why this natural fiber is so extraordinary.

What is Mulberry Silk

Silk is a natural protein fiber produced by silkworms as they feed on mulberry leaves. The silkworms spin these fibers into a protective cocoon around themselves. This cocoon is the raw material used to create silk fabric.

To turn these cocoons into beautiful silk fabric, people unwind the long, thin silk threads and weave them together. Let’s delve into the detailed process of silk production, from silkworm rearing to fabric weaving.

Step 1. Mulberry Cultivation and Silkworm Rearing

The journey begins with the mulberry tree, whose leaves are the sole food source for Bombyx mori silkworms. These trees are carefully cultivated to ensure a clean, nutritious diet for the silkworms—because better leaves mean better silk.

Silkworms are raised in controlled environments to ensure they grow healthy and safe. Over about 25 to 30 days, they feed continuously, growing from tiny hatchlings to fat, happy worms ready to spin their cocoons.

From tiny eggs to silky cocoons, raising silkworms is a fascinating journey. It involves three main steps: hatching, feeding, and spinning. Each step is crucial for producing high-quality silk.

1. Hatching the eggs

Each spring, as temperatures rise and nature awakens, it is the optimal time for silkworm eggs to hatch. To accelerate the hatching process, the eggs can be exposed to sunlight, a traditional practice in China known as “yucan(浴蚕)” .

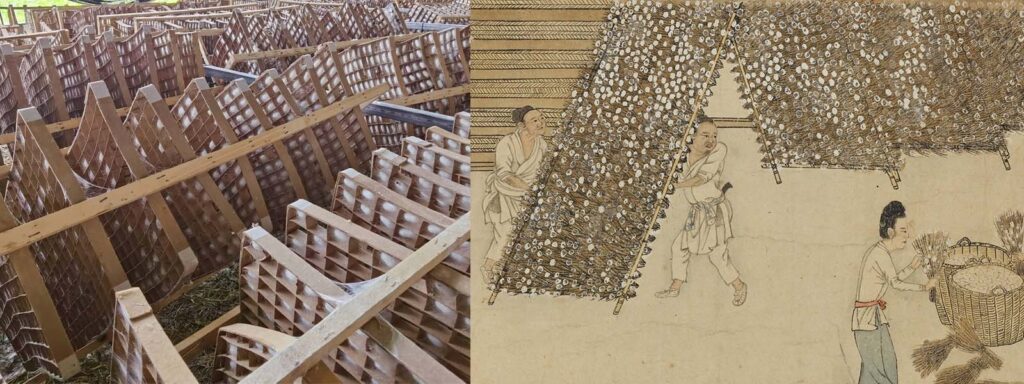

Newly hatched silkworms are delicate and should be placed on clean white paper before being transferred to a silkworm basket, a traditional and still widely used tool in silkworm rearing. While modern silk farmers may employ more advanced equipment, the bamboo silkworm basket remains a staple in the industry.

2. Feeding the worms

Baby silkworms are very tiny and weak. They need to eat soft and fresh mulberry leaves. As they grow bigger, they can eat tougher leaves. It’s important to keep the leaves dry to prevent the silkworms from getting sick. Modern silkworm farms are very clean and germ-free.

The silkworm, or domesticated silk moth, undergoes four molting stages during its larval phase, resulting in five instars. These molting cycles are crucial for the silkworm to grow and develop.

- First Instar: Upon hatching, the tiny silkworm, often referred to as an “ant silkworm” due to its size, enters its first instar. After approximately 3-4 days, it molts into the second instar.

- Second Instar: Following the first molt, the silkworm enters the second instar and continues to feed and grow for another 3-4 days before molting again.

- Third Instar: After the second molt, the silkworm enters the third instar. This stage, along with the first two, is collectively known in ancient China as the “three sleeps(三眠)” due to the quiescent period before each molt.

- Fourth Instar: The silkworm molts again after about 3-4 days in the third instar, entering the fourth instar.

- Fifth Instar: The final molt marks the beginning of the fifth instar. In this stage, the silkworm experiences significant growth and its appetite increases dramatically. The Chinese term for this final molt is “great rise(大起)” The silkworm’s feeding activity becomes so intense during this stage that it sounds like a gentle rain. After approximately 6-8 days of rapid growth in the fifth instar, the silkworm ceases feeding.

These molting cycles are essential for the silkworm’s growth and development, allowing it to accommodate its increasing size and prepare for the final stage of its life: cocoon spinning.

3. Spinning cocoons

As the silkworm nears the end of its larval stage, it begins the process of cocoon formation. The silkworm’s body shortens and becomes translucent with a golden hue. At this point, the silkworm is carefully transferred to a special frame or rack, a process known as “mounting(上簇).” The frame is often made of bamboo, wood, or other materials and provides a structure for the silkworm to spin its cocoon. Modern silk farms often use specially designed gridded frames that allow for easier handling of the cocoons.

The silkworm spins silk to form a cocoon with a high content of sericin and uneven thickness.

- The silkworm begins by spinning a loose, irregular layer of silk, known as the outer cocoon layer or floss,

- Then the silkworm’s body begins to bend into a “C” shape, and its head and thorax move rhythmically, spinning silk in “S” or “8” patterns. This process proceeds from front to back, layering the silk. Once a certain thickness is achieved in one spot, the silkworm shifts to another location and continues, layer by layer, forming silk sheets. These silk sheets are held together by sericin, creating a cocoon layer.

- In the later stages of cocoon formation, the silkworm’s body significantly shrinks, its head movements slow down and become uncoordinated, and the spinning becomes irregular. The silk gradually contains less sericin and becomes loose, forming a disordered silk layer inside the cocoon, known as the “pupal lining.”

Eventually, the silkworm is completely enclosed within the cocoon, where it will pupate and eventually emerge as a moth.

Step 2: Harvesting and Boiling the Cocoons

Once the silkworms complete their cocoons—typically after 3 to 4 days of spinning—the cocoons are carefully harvested by hand. Timing is key here. If the cocoon is left too long, the moth will emerge and break the continuous silk thread, making it unsuitable for high-quality silk production.

To preserve the precious filament, the harvested cocoons are gently boiled or steamed. This process serves two purposes:

- It loosens the sericin, the natural protein that acts as glue to hold the cocoon together.

- It prevents the moth from breaking out, maintaining the silk’s long, unbroken structure.

Though it sounds simple, this step requires careful handling to avoid damaging the delicate silk. It’s an essential moment in transforming a raw cocoon into a viable source of silk thread.

Step 3: Reeling the Silk

After boiling, the softened cocoons are transferred into warm water to begin the reeling process, also known as “filature.” This is where the magic begins: skilled workers or machines carefully locate the loose end of the silk filament—a task that demands both dexterity and patience.

Each cocoon yields a continuous silk thread that can measure over 1,000 meters long. However, because a single filament is too fine to use alone, 5 to 8 filaments are combined and twisted together to create one strand of raw silk.

This meticulous work is what gives mulberry silk its signature smoothness and strength. The precision required at this stage is one of the key reasons mulberry silk is considered such a luxurious, labor-intensive material.

Step 4: Twisting, Dyeing, and Weaving

Once reeled, the raw silk threads undergo a series of transformations to become the fabric we know and love. The next steps include:

- Twisting the raw threads into stronger silk yarns, which improves durability and flexibility.

- Dyeing the yarns with either natural plant-based dyes or modern synthetic pigments, depending on the desired color vibrancy and fastness.

- Weaving the dyed threads on traditional handlooms or advanced power looms to create silk fabrics in various textures.

From smooth charmeuse and crisp organza to soft crepe de chine and shimmering satin, the weaving technique determines the final look and feel of the silk. Every detail, from thread tension to weaving pattern, affects the texture, weight, and drape of the finished product.

This phase is both technical and artistic, requiring deep knowledge of textile craft to create fabrics that are not only beautiful but also durable and wearable.

Step 5: More Processing: Jacquard and Embroidery

Once the solid silk fabric is finished and decorative processes that bring out its full beauty and functionality. These treatments not only enhance the appearance of the fabric but also improve its texture, durability, and versatility.

🔹 Jacquard Weaving

For more intricate designs, silk can also be woven using Jacquard looms, which allow for complex patterns to be integrated directly into the fabric. These patterns, ranging from florals and geometrics to traditional Chinese motifs, are not printed or embroidered, but woven right into the material using multiple threads and color changes.

Jacquard silk is especially prized for its rich texture, visual depth, and timeless elegance, often used in high-end fashion and home décor.

🔹 Embroidery and Artistic Enhancements

In addition to woven patterns, silk fabric may be further decorated through hand or machine embroidery. Skilled artisans add fine details using colored threads, sometimes incorporating sequins, beads, or metallic accents.

Embroidery on silk has a long history, particularly in China, and adds a unique artistic value to each piece. It transforms plain fabric into wearable art or heirloom-quality decor.

While warp and weft are the primary yarns in weaving, there are many other techniques that can be used to create different types of fabrics. For example, twisting and twill weaving can produce a variety of fabrics. In ancient China, fabrics like silk crepe, gauze, satin, and damask were commonly produced. By adding elastic materials, it was also possible to create stretchy silk fabrics.

FAQ: Common Questions About Mulberry Silk

Silk Applications

Silk, renowned for its luxurious feel, durability, and natural beauty, finds a wide range of applications in the textile industry: Apparel, Sleepwear, Bed linens, Hair Accessories, Home decor, and more. From everyday wear to high-end fashion, silk’s versatility makes it a sought-after material.

Look for more information on the applications of silk :

👉 Check more Mulberry Silk products here ➞

Summary for How Mulberry Silk is Made

From a tiny silkworm nibbling on mulberry leaves to a flowing piece of elegant fabric, the making of mulberry silk is a true labor of love. Each step, from careful sericulture to delicate reeling and expert weaving, reflects centuries of craftsmanship, patience, and precision.

But silk is more than just a beautiful textile. It’s a living tradition, woven into the cultural and artistic heritage of civilizations across time. Over the centuries, the techniques have evolved, but the heart of silk-making remains the same: a deep respect for nature, skillful hands, and a pursuit of timeless beauty.

When you wrap yourself in mulberry silk, you’re not just wearing a fabric, you’re experiencing a story that spans thousands of years.